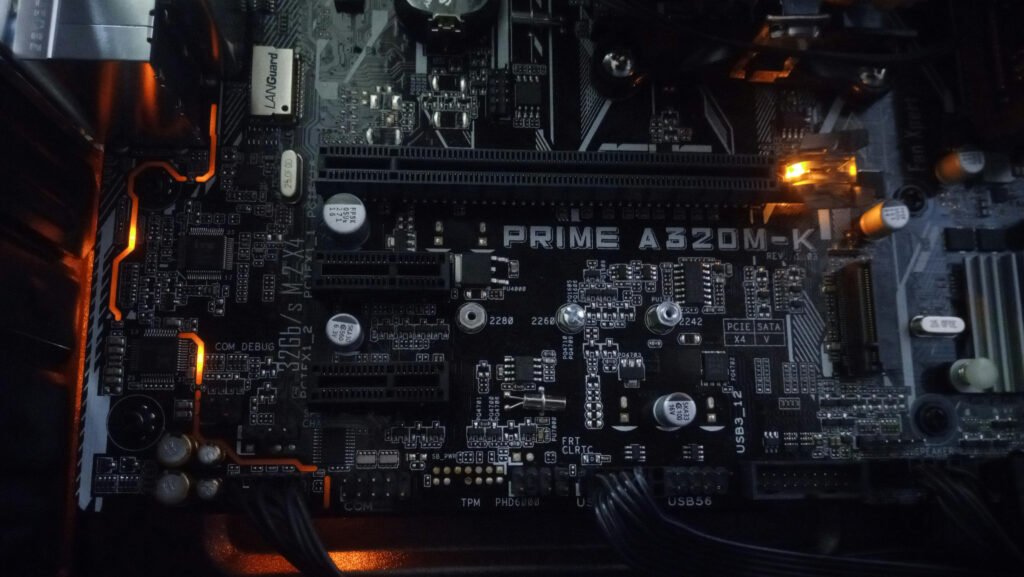

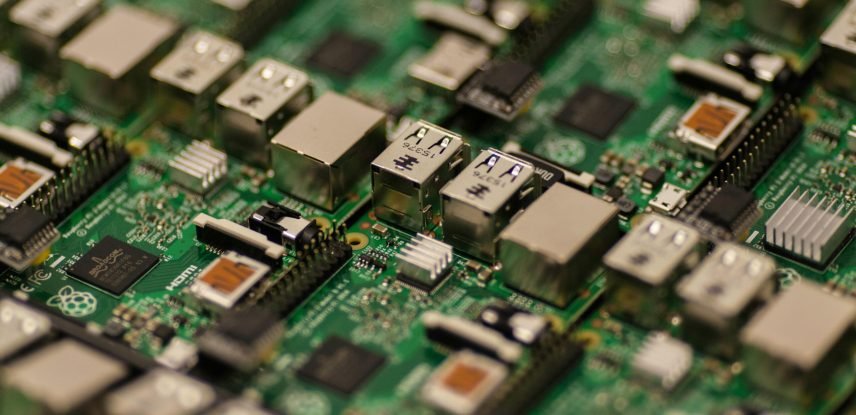

Hardware Design

From concept to production-ready hardware, engineered with precision, purpose, and manufacturability in mind.

Engineering the Physical Future

We design high-performance circuitry and robust physical architectures that turn complex electronic concepts into market-ready hardware.

Services

Our Problems

The Problems We Solve

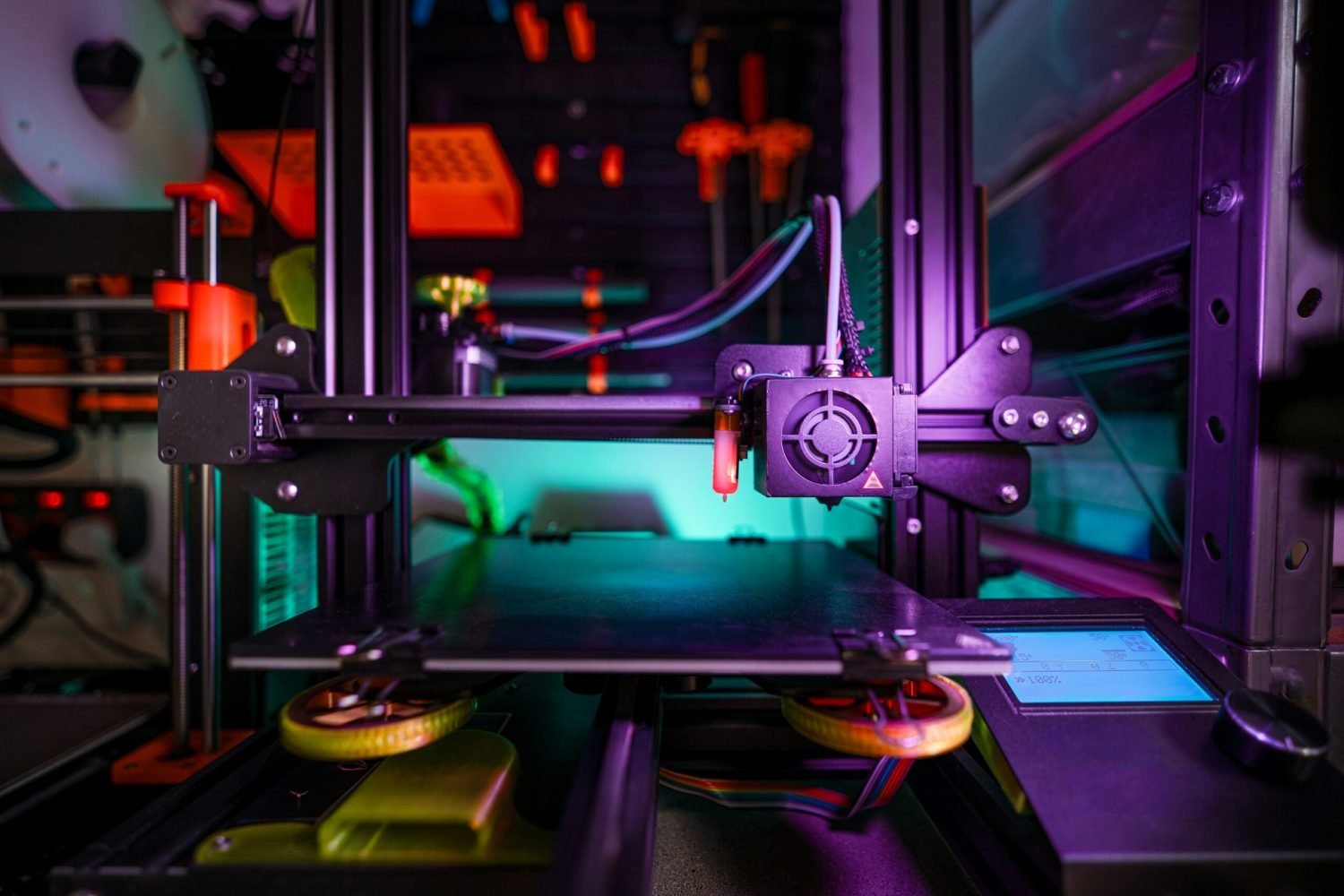

Clients often struggle with hardware that is too expensive to manufacture or fails to meet regulatory standards. Many face “feature creep” that delays production or find that their prototypes aren’t scalable for mass assembly. We eliminate these hurdles by designing for manufacturability (DFM) from day one. We also solve issues related to overheating, power inefficiency, and poor signal quality in compact devices.

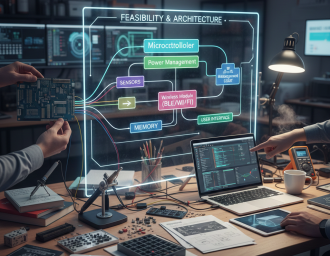

Our Process

The Problems We Solve

Clients often struggle with hardware that is too expensive to manufacture or fails to meet regulatory standards. Many face “feature creep” that delays production or find that their prototypes aren’t scalable for mass assembly. We eliminate these hurdles by designing for manufacturability (DFM) from day one. We also solve issues related to overheating, power inefficiency, and poor signal quality in compact devices.

Our Result

The Problems We Solve

Clients often struggle with hardware that is too expensive to manufacture or fails to meet regulatory standards. Many face “feature creep” that delays production or find that their prototypes aren’t scalable for mass assembly. We eliminate these hurdles by designing for manufacturability (DFM) from day one. We also solve issues related to overheating, power inefficiency, and poor signal quality in compact devices.